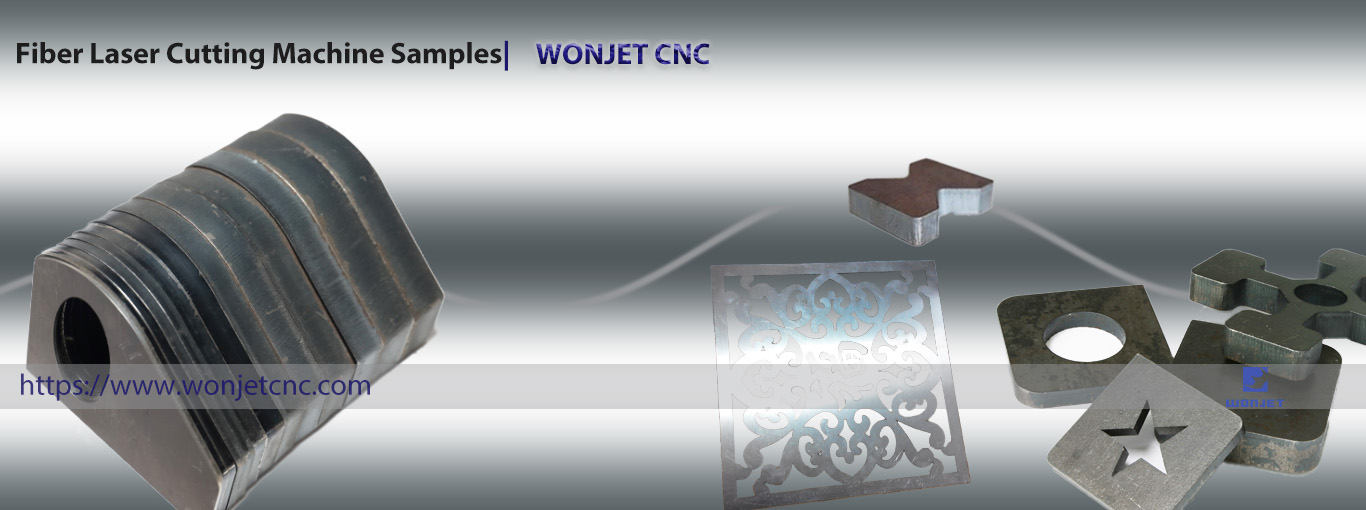

Industry Applications of Fiber Laser Cutting Machine

The Fiber Laser Cutting Machine mainly used in sheet metal processing, aviation, aerospace, electronics, electrical appliances, subway accessories, automobiles, food machinery, textile machinery, construction machinery, precision accessories, ships, metallurgical equipment, elevators, household appliances, craft gifts, tool processing, decoration, advertising, metal external processing, kitchen utensils processing and other manufacturing and processing industries.

Specifications of Fiber Metal Cutting Machine

| Model | WJ-3015 |

| Working Area | 3000*1500mm(Optional) |

| Driving System | Japan Fuji servo or Yaskawa servo(optional) |

| Controller system | Cypcut System |

| Laser cutting head | Raytools cutting head |

| X.Y Guiding System | Taiwan 25 |

| Rack | Germany 1.5m |

| Interface | LCD screen with USB interface |

| Supported Format | BMP. HPGL(PLT), DXF, G-CODE, DST, AI |

| Working Voltage | AC380V/ 50HZ |

Features of Fiber Laser Cutting Machine

- High precision, high speed, narrow slit, minimum heat affected zone, smooth cutting surface without burrs.

- The laser cutting head will not contact the surface of the material and will not scratch the workpiece.

- The slit is the narrowest, the heat-affected zone is the smallest, the local deformation of the workpiece is extremely small, and there is no mechanical deformation.

- It has good processing flexibility, can process any graphics, and can also cut pipes and other special-shaped materials.

- Non-deformation cutting can be performed on materials of any hardness such as steel plates, stainless steel, aluminum alloy plates, and hard alloys.