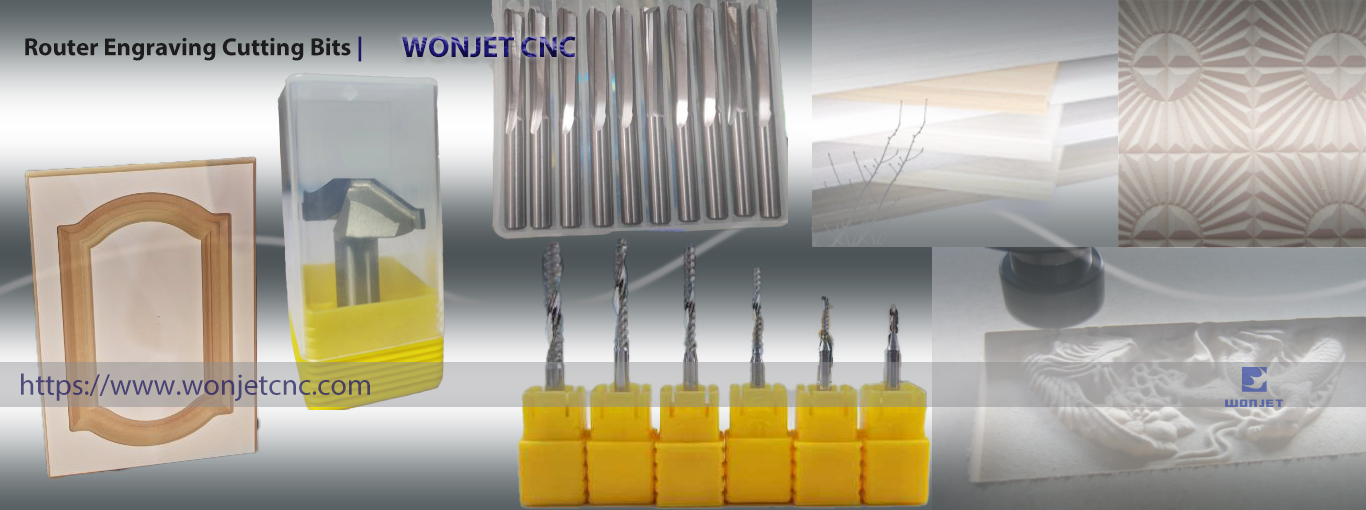

Industry Applications of Wood Engraving bits

The engraving bits are used on the CNC engraving router machine. The traditional manual engraving can no longer meet the needs of the actual development. Nowadays engraving machine has a wide range of applications, such as advertising engraving, furniture engraving, handicraft engraving, gold and silver engraving. cabinets carving, electronic products, molds, etc. all require CNC engraving machines. The router engraving bit as the consumption parts of the CNC wood engraving router, its quality is very important to the machine engraving speed and working precision. Better bits are greatly improved the machine work efficiency.

Features and Usages of Milling Engraving Bits

The Milling bits Generally divided into:

- Flat-end milling cutter: used to do rough milling, remove a large amount of blank of the materials surface, small area horizontal plane or contour fine milling.

- Ball end milling cutter: mainly for semi-finishing and finish milling of curved surfaces; small cutters can finish milling small chamfers on steep surfaces/straight walls.

- The flat end milling cutter wither chamfering: which can do rough milling to remove a large amount of surface blanks and can also finely mill small chamfers on the fine flat front (relative to the steep surface).

- Forming milling cutters: including chamfering cutters, T-shaped milling cutters or drum cutters, tooth cutters, and inner R cutters.

- Chamfering cutter: the shape of the chamfering cutter is the same as that of the chamfering, and it is divided into milling cutters for rounding and chamfering.

- T-shaped knife: can mill T-shaped groove.

- Tooth cutter: milling out various tooth shapes, such as gears.

- Rough skin cutter, a rough milling cutter designed for cutting aluminum and copper alloys, which can be processed quickly.