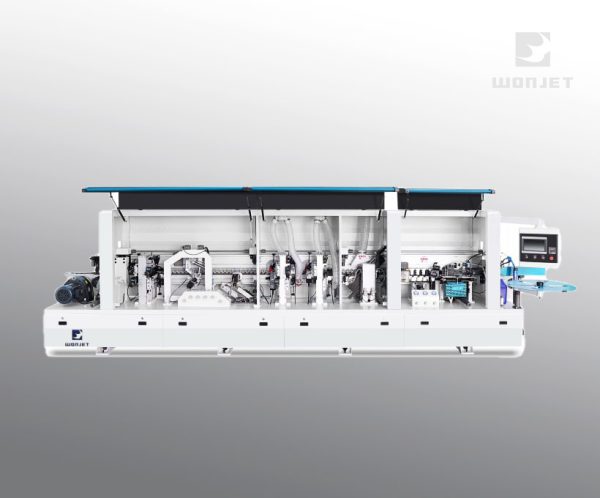

Industry Applications of Edge Banding Machine

The edge banding machine is a programmed edge banding machine that replaces manual processing of wooden doors or format cabinets: conveying – gluing and welting – end cutting – front and rear alignment – upper and lower trimming – upper and lower finishing edges – upper and lower Scraping – polishing, etc., a highly automated machine, mainly divided into semi-automatic, portable, and fully automatic model.

Specifications of Wood Door Cabinets Edge Bander

| Model | WJ-375M |

| Control system | Taiwan Delta Touchable PLC |

| Feeding Speed | 18-23m/min |

| Edge Thickness | 0.4-3mm |

| Panel Thickness | 10-55mm |

| Panel Length | Min.120mm |

| Panel Width | Min.60mm |

| Work pressure | 0.6Mps |

| Motor Power | 12.5kw |

| Machine Overall Size | 5760*900*1560mm |

Function of Edge Banding Machine

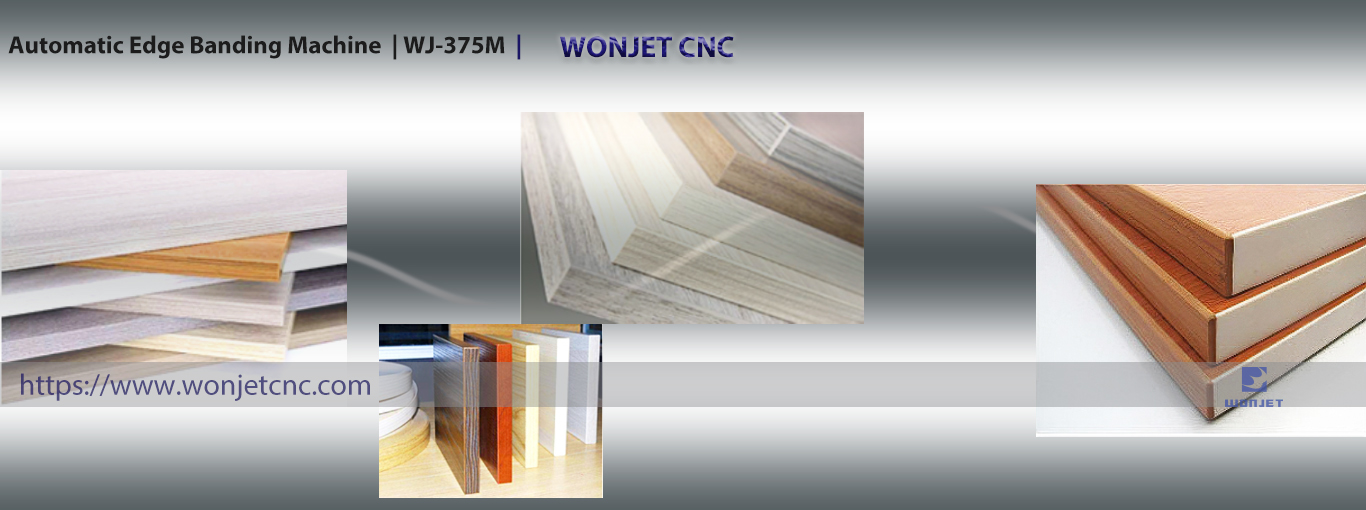

- This machine is suitable for straight edge trimming and trimming of medium density fiberboard, blockboard, solid wood board, particle board, polymer door panel, plywood, etc. Flush, Chamfer, Rough Trim, Fine Trim, Profile Tracking round cornering, scraping and polishing, etc.

- After edge sealing with the edge banding machine, the wood products will with good handle feeling, and the sealing line is straight and smooth.

- This model automatic edge banding machine is stable, reliable and durable, and the price is moderate. It is especially suitable for manufacturers of large and medium-sized furniture, cabinets and other panel furniture.